1. Fe-based nanocrystalline soft magnetic materials

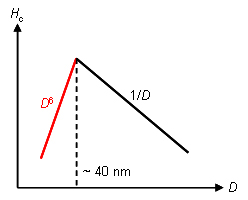

Nanocrystalline

soft magnetic materials consist of ultra-fine ferromagnetic

crystallites with size of approximately 10 nm. Owing to strong

ferromagnetic exchange coupling between the nanocrystallites, their

magnetocrystalline anisotropy is averaged out and the materials exhibit

good soft magnetic properties (Fig. 1).

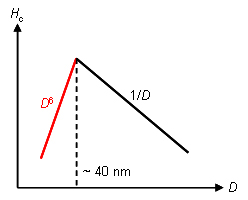

Fig. 1 Relationship between crystalline size (

D) and coercivity (

Hc)

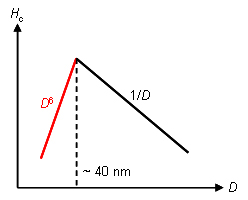

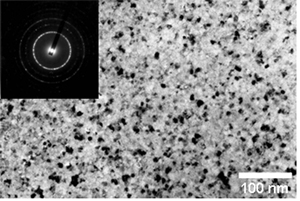

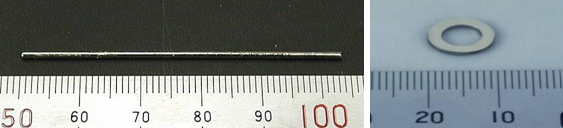

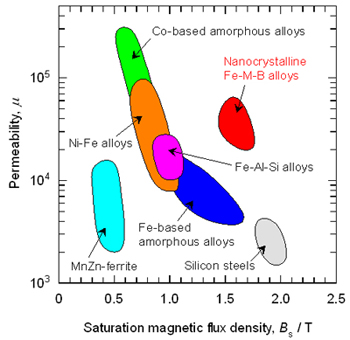

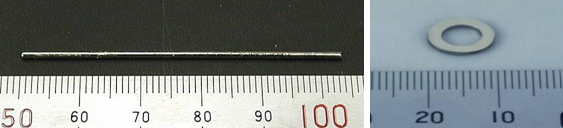

We are

investing the microstructure and the magnetic properties of the

nanocrystalline Fe-M-B (M = Zr, Hf, Nb) soft magnetic alloys. The

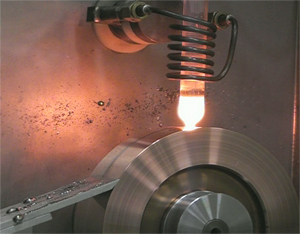

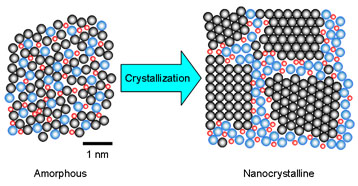

nanocrystalline alloys are produced by the crystallizing the melt-spun

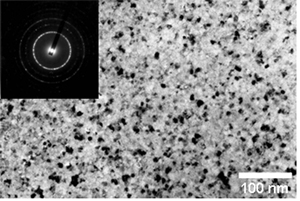

(Fig. 2) amorphous phase (Fig. 3). The resultant alloys have a mixed

structure consist of nanoscale ¿-Fe phase (crystalline size is approximately 10 nm)

embedded in a ferromagnetic amorphous matrix (Fig. 4). The

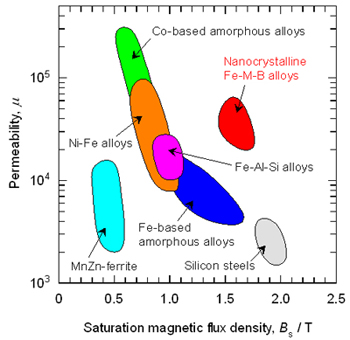

nanocrystalline Fe-M-B (M = Zr, Hf, Nb) soft magnetic alloys exhibit

the high permeability as well as the high saturation magnetic flux

density (Fig. 5).

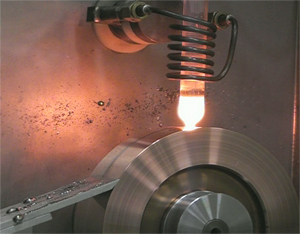

Fig. 2 Melt-spinning apparatus

(Please click the photograph to play the movie.

Windows Media Player is required.)

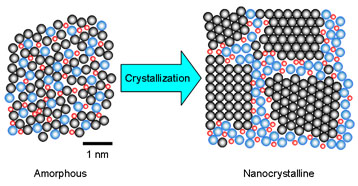

Fig. 3 Schematic image of nanocrystallization

Fig. 4 TEM image of nanocrystalline Fe-Nb-B alloy

Fig. 5 Relationship between saturation magnetic flux density (

Bs) and permeability (

Ê)

Related Publications

- T. Bitoh, A. Makino and A. Inoue, gThe Effect of Grain-Size Distribution on Coercivity in Nanocrystalline Soft Magnetic Alloys,h Journal of Magnetism and Magnetic Materials, vols. 272–276, pp. 1445–1446 (2004).

- T. Bitoh, A.

Makino, A. Inoue and T. Masumoto, gRandom Anisotropy Model for

Nanocrystalline Soft Magnetic Alloys with Grain-Size Distribution,h

Materials Transactions, vol. 44, no. 10, pp. 2011–2019 (2003).

2. Fe-(Pt, Pd)-based nanocrystalline hard magnetic materials

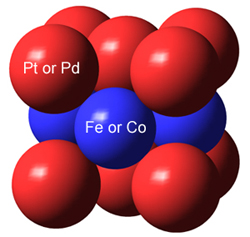

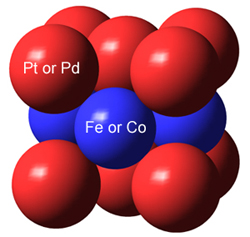

The ordered L10 alloys (Fig. 6)

such as Fe-Pt, Co-Pt, Fe-Pd have long been anticipated as materials for

permanent magnets because of their large magnetocrystalline anisotropy

and good corrosion resistance. However, near equiatomic FePt cast

alloys do not exhibit high magnetic hardness because of their

coarsening structure.

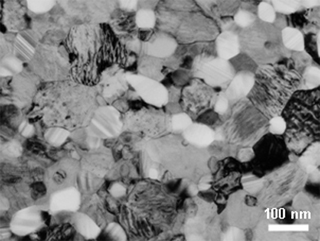

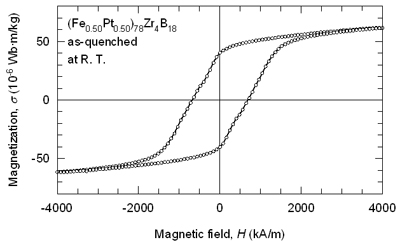

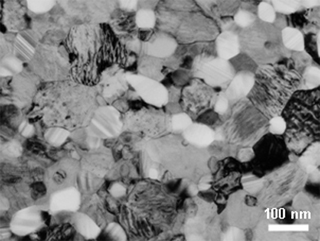

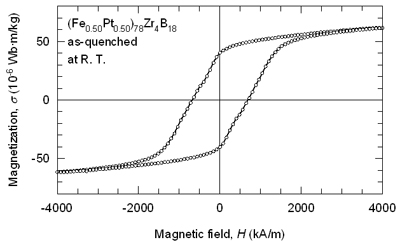

We are investing the microstructure and the magnetic properties of the

nanocrystalline (Fe, Pt)-M-B (M = Zr, Hf, Ti) hard magnetic alloys. The

simultaneous addition of transition metals and B to the Fe-Pt alloy

remarkably decreases its melting temperature. The L10-FePt phase with a size of approximately 100 nm can be directly synthesized (Fig. 7) by rapidly quenching of the melt (Fig. 2)

without allowing the formation of the disordered fcc phase, and the

high coercivity of 688 kA/m, which is much higher than that of the

annealed bulk Fe-Pt, is obtained for the melt-spun (Fe0.50Pt0.50)78Zr4B18 alloy in an as-quenched state (Fig. 8).

Fig. 6 Unit cell of L1

0 ordered alloys

Fig. 7 TEM image of nanocrystalline Fe-Pt-Zr-B alloy

Fig. 8 Magnetization curve of melt-spun Fe-Pt-Zr-B alloy in an as-quenched state

Related Publications

- T. Bitoh, M.

Nakagawa and A. Makino, gMelting Temperature and Order-Disorder

Transformation of Melt-Spun (Fe, Pt)-Zr-B Nanocrystalline Alloys,h

Scripta Materialia, vol. 53, no. 4, pp. 429–434 (2005).

- T. Bitoh, A.

Makino and M. Nakagawa, gMicrostructure and Hard Magnetic Properties of

Directly Synthesized L10 (Fe1–xPtx)78Zr4B18 Nanocrystalline Alloys by

Melt-Spinning,h Journal of Applied Physics, vol. 97, no. 10, 10H307

(2005) (3 pages).

3. Fe-based bulk metallic glasses

Recently, a number of amorphous alloys exhibit a wide supercooled liquid region (¢Tx)

before crystallization. The appearance of the wide supercooled liquid

region implies that the alloys have high resistance against

crystallization. Consequently, these alloys with large ¢Tx

values have been confirmed to have an extremely large glass-forming

ability, which enables the production of bulk metallic glasses (Fig. 9).

Fig. 9 Fe-based bulk metallic glasses produced by Cu-mold casting

It is

well know that Fe- and Co-based ordinary amorphous alloys exhibit good

soft magnetic properties. The origin of the good soft magnetic

properties is lack of long-range atomic order (the left figure in Fig. 3).

This feature is also common in the bulk metallic glasses. It seems that

therefore, the soft magnetic properties of the bulk metallic glasses

are same as those of the ordinary amorphous alloys. Is this assumption

correct?

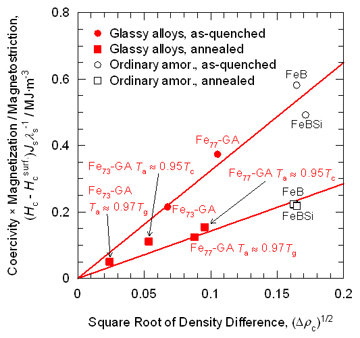

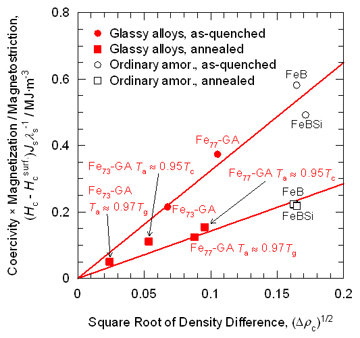

We are investing the magnetic properties of the Fe-based bulk metallic

glasses. The bulk metallic glasses exhibit lower coercivity (Hc) than that of the ordinary amorphous alloys (Fig. 10). The low Hc originates from the much higher packing density of the bulk metallic glasses

than that of the ordinary amorphous alloys, which realizes the low

density of the pinning centers for magnetic domain-walls. The good

combination of high glass-forming ability and good soft magnetic

properties indicates the possibility of future development as a new

bulk glassy soft magnetic material.

Fig. 10 Relationship between density (

Ï) and coercivity (

Hc) of Fe-based bulk metallic glasses and ordinary amorphous alloys

Related Publications

- T. Bitoh, A.

Makino and A. Inoue, gOrigin of Low Coercivity of

(Fe0.75B0.15Si0.10)100–xNbx (x = 1–4) Glassy Alloys,h Journal of

Applied Physics, vol. 99, no. 8, 08F102 (2006) (3 pages).

- T. Bitoh, A.

Makino and A. Inoue, gMagnetization Process and Coercivity of Fe-(Al,

Ga)-(P, C, B, Si) Soft Magnetic Glassy Alloys,h Materials Transactions,

vol. 45, no. 4, pp. 1219–1227 (2004).

- T. Bitoh, A.

Makino and A. Inoue, gOrigin of Low Coercivity of Fe-(Al, Ga)-(P, C, B,

Si, Ge) Bulk Glassy Alloys,h Materials Transactions, vol. 44, no. 10,

pp. 2020–2024 (2003).

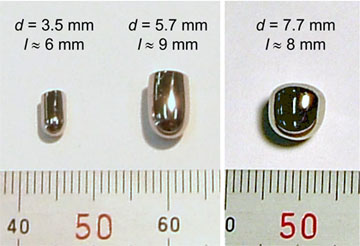

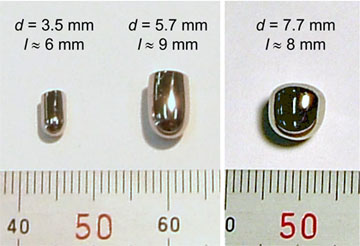

The Fe-(Co, Ni) based bulk metallic glasses exhibit good soft magnetic properties, described above. However, the glass-forming ability of the soft magnetic bulk metallic glasses

is inferior to that of the nonferrous alloys such as Pd-, Zr-,

lanthanide-, and Mg-based alloys. It is well known that the main

competition to prepare bulk metallic glasses

is attributed to oxides and other inclusion in the molten metal which

act as heterogeneous nucleation sites for crystallization. An approach

to eliminate the inclusions is to heat and cool the molten metal while

it is immersed in molten oxide flux. Recently, we have succeeded in the

synthesis of the large soft magnetic [(Fe0.5Co0.5)0.75B0.20Si0.05]96Nb4 bluk metallic glass specimens with the diameters up to 7.7 mm by water quenching the melt immersed in the molten flux of B2O3 (Fig. 11).

The maximum diameter of the obtained specimens is approximately 1.5

times as large as the previous result for copper mold casting. This

bulk specimen is the thickest of any soft magnetic bulk metallic glasses formed until now.

Fig. 11 Soft magnetic

bulk metallic glasses prepared by B

2O

3 flux melting and water quenching technique

Related Publications

- T. Bitoh, A.

Makino, A. Inoue and A. L. Greer, gLarge Bulk Soft Magnetic

[(Fe0.5Co0.5)0.75B0.20Si0.05]96Nb4 Glassy Alloy Prepared by B2O3 Flux

Melting and Water Quenching,h Applied Physics Letters, vol. 88, no. 18,

182510 (2006) (3 pages).

- T. Bitoh, A.

Makino, A. Inoue and A. L. Greer, gFormation of Large Bulk

[(Fe0.5Co0.5)0.75B0.20Si0.05]96Nb4 Glassy Alloy by Flux Melting and

Water Quenching,h Materials Research Society Symposium Proceedings,

eds. E. Ma, S. Schuh, Y. Li and M. K. Miller (Boston, Materials

Research Society, 2006) vol. 903E, Z05–18 (6 pages).

Go to: Top of my home page

Last modified on March 28th, 2019